(408)9306636 pcbusa@pcbdoc.com

Language : 中文

Edadoc

Technical Articles

-

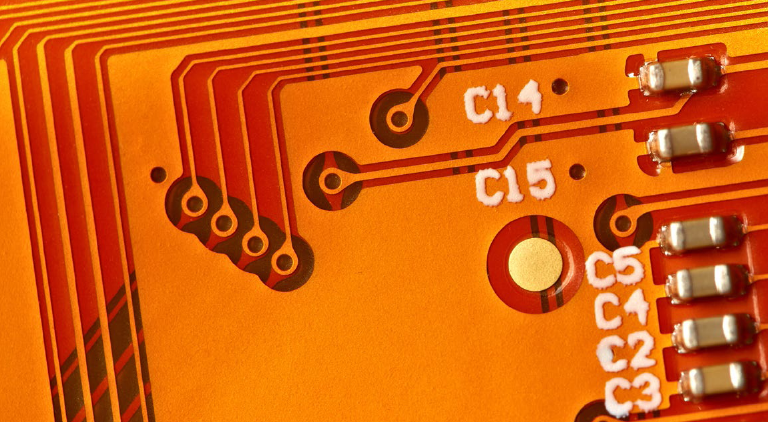

How to Avoid EMC Problems in PCB Design

Electromagnetic Compatibility (EMC), Signal Integrity (SI), and Power Integrity (PI) are

closely related. We must maintain SI & PI performance and consider stack-up

& shield isolation in order to avoid EMC problems when laying out a PCB.

Source :Edadoc 2018/11/3>>Detail

Electromagnetic Compatibility (EMC), Signal Integrity (SI), and Power Integrity (PI) are

closely related. We must maintain SI & PI performance and consider stack-up

& shield isolation in order to avoid EMC problems when laying out a PCB.

Source :Edadoc 2018/11/3>>Detail

-

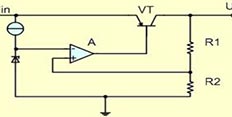

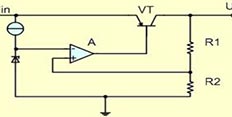

Switching vs. Linear Regulators

We will analyze the pros and cons of Switching regulators (DC-to-DC) and Linear regulators (LDO) in order to determine the best option for PCB Design.

Source :Edadoc 2018/9/17>>Detail

We will analyze the pros and cons of Switching regulators (DC-to-DC) and Linear regulators (LDO) in order to determine the best option for PCB Design.

Source :Edadoc 2018/9/17>>Detail

-

Flexible Circuit Component Assembly and a Math Lesson.

The market for rigid PCBs is estimated to be about 10x the market size

for flexible printed circuits (FPCs). As a result, the equipment

infra-structure is driven primarily by the needs of the rigid board

market. This is true of both equip-ment used to fabricate the circuitry

(image, etch, copper plate, AOI, etc.) and equipment used for component

assembly (wave solder and SMT assembly).

The market for rigid PCBs is estimated to be about 10x the market size

for flexible printed circuits (FPCs). As a result, the equipment

infra-structure is driven primarily by the needs of the rigid board

market. This is true of both equip-ment used to fabricate the circuitry

(image, etch, copper plate, AOI, etc.) and equipment used for component

assembly (wave solder and SMT assembly).

Source :Edadoc 2018/3/2>>Detail

-

Process Engineering: PCB Manufacturing’s “Delta Force”

The role of the process engineer is arguably one of the most important

jobs in the printed circuit industry. The process engineer is on the

front line of manufacturing and responsible for making sure product

yields and profitability meet expectations.

Source :Edadoc 2017/4/12>>Detail

The role of the process engineer is arguably one of the most important

jobs in the printed circuit industry. The process engineer is on the

front line of manufacturing and responsible for making sure product

yields and profitability meet expectations.

Source :Edadoc 2017/4/12>>Detail

-

The Evolution of FR-4

In the past 40-plus years of PCB manufacturing, the primary material of

choice has overwhelmingly been e-glass supported FR-4 resin laminates.

This is due to the excellent dimensional stability and reasonably

acceptable thermal performance (based on glass transition temperature

[Tg] and decomposition temperature [Td]). In general, these materials

exhibit impressive performance and excellent cost for a wide range of

applications.

Source :Edadoc 2016/5/6>>Detail

In the past 40-plus years of PCB manufacturing, the primary material of

choice has overwhelmingly been e-glass supported FR-4 resin laminates.

This is due to the excellent dimensional stability and reasonably

acceptable thermal performance (based on glass transition temperature

[Tg] and decomposition temperature [Td]). In general, these materials

exhibit impressive performance and excellent cost for a wide range of

applications.

Source :Edadoc 2016/5/6>>Detail

-

Why Copper is Ideal for Flexible Circuitry?

While copper may not rank the best in any one of the above criteria, it probably has the best overall rating.

While copper may not rank the best in any one of the above criteria, it probably has the best overall rating.

Source :Edadoc 2016/4/14>>Detail

-

Design for Test in the U.S. Market.

With most high-volume printed circuit assembly being sent outside the

United States, we have a unique challenge for testing the lower

volume/high turnover assemblies domestically. However, with a little

planning and the right contract manufacturer (CM), test does not need to

be an issue.

Source :Edadoc 2016/4/7>>Detail

With most high-volume printed circuit assembly being sent outside the

United States, we have a unique challenge for testing the lower

volume/high turnover assemblies domestically. However, with a little

planning and the right contract manufacturer (CM), test does not need to

be an issue.

Source :Edadoc 2016/4/7>>Detail

-

Why Do Different Test Methods Yield Different Electrical Values?

A variety of different test methods may be used for any one electrical

concern. This article will discuss the issues related to determining the

dielectric constant (Dk) and dissipation factor (Df or Tan-Delta).

Source :Edadoc 2016/3/30>>Detail

A variety of different test methods may be used for any one electrical

concern. This article will discuss the issues related to determining the

dielectric constant (Dk) and dissipation factor (Df or Tan-Delta).

Source :Edadoc 2016/3/30>>Detail

-

3D Assembly Processes: A Look at Today and Tomorrow

Printed circuit board

assembly (PCBA), starting with the plated through-hole, later evolving

to surface mount assembly, have been planar in two dimensions.

Components are mounted onto the PCBA in the x and y direction, where the

height, z direction, is controlled by the component height.

Printed circuit board

assembly (PCBA), starting with the plated through-hole, later evolving

to surface mount assembly, have been planar in two dimensions.

Components are mounted onto the PCBA in the x and y direction, where the

height, z direction, is controlled by the component height.

Source :Edadoc 2016/3/2>>Detail

-

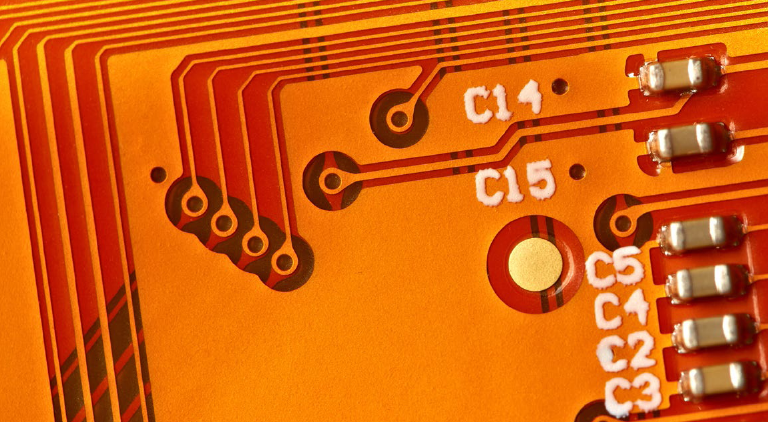

How does the EDADOC PCBA factory work?

How does the EDADOC PCBA factory work with 12 SMT lines? Edadoc PCBA factory devoted to cooperate with our clients, thus offers great product experience to end customers.

How does the EDADOC PCBA factory work with 12 SMT lines? Edadoc PCBA factory devoted to cooperate with our clients, thus offers great product experience to end customers.

Source :Edadoc 2016/2/25>>Detail

Electromagnetic Compatibility (EMC), Signal Integrity (SI), and Power Integrity (PI) are

closely related. We must maintain SI & PI performance and consider stack-up

& shield isolation in order to avoid EMC problems when laying out a PCB.

Source :Edadoc 2018/11/3>>Detail

Electromagnetic Compatibility (EMC), Signal Integrity (SI), and Power Integrity (PI) are

closely related. We must maintain SI & PI performance and consider stack-up

& shield isolation in order to avoid EMC problems when laying out a PCB.

Source :Edadoc 2018/11/3>>Detail

We will analyze the pros and cons of Switching regulators (DC-to-DC) and Linear regulators (LDO) in order to determine the best option for PCB Design.

Source :Edadoc 2018/9/17>>Detail

We will analyze the pros and cons of Switching regulators (DC-to-DC) and Linear regulators (LDO) in order to determine the best option for PCB Design.

Source :Edadoc 2018/9/17>>Detail

The market for rigid PCBs is estimated to be about 10x the market size

for flexible printed circuits (FPCs). As a result, the equipment

infra-structure is driven primarily by the needs of the rigid board

market. This is true of both equip-ment used to fabricate the circuitry

(image, etch, copper plate, AOI, etc.) and equipment used for component

assembly (wave solder and SMT assembly).

The market for rigid PCBs is estimated to be about 10x the market size

for flexible printed circuits (FPCs). As a result, the equipment

infra-structure is driven primarily by the needs of the rigid board

market. This is true of both equip-ment used to fabricate the circuitry

(image, etch, copper plate, AOI, etc.) and equipment used for component

assembly (wave solder and SMT assembly).  The role of the process engineer is arguably one of the most important

jobs in the printed circuit industry. The process engineer is on the

front line of manufacturing and responsible for making sure product

yields and profitability meet expectations.

Source :Edadoc 2017/4/12>>Detail

The role of the process engineer is arguably one of the most important

jobs in the printed circuit industry. The process engineer is on the

front line of manufacturing and responsible for making sure product

yields and profitability meet expectations.

Source :Edadoc 2017/4/12>>Detail

In the past 40-plus years of PCB manufacturing, the primary material of

choice has overwhelmingly been e-glass supported FR-4 resin laminates.

This is due to the excellent dimensional stability and reasonably

acceptable thermal performance (based on glass transition temperature

[Tg] and decomposition temperature [Td]). In general, these materials

exhibit impressive performance and excellent cost for a wide range of

applications.

Source :Edadoc 2016/5/6>>Detail

In the past 40-plus years of PCB manufacturing, the primary material of

choice has overwhelmingly been e-glass supported FR-4 resin laminates.

This is due to the excellent dimensional stability and reasonably

acceptable thermal performance (based on glass transition temperature

[Tg] and decomposition temperature [Td]). In general, these materials

exhibit impressive performance and excellent cost for a wide range of

applications.

Source :Edadoc 2016/5/6>>Detail

While copper may not rank the best in any one of the above criteria, it probably has the best overall rating.

While copper may not rank the best in any one of the above criteria, it probably has the best overall rating. With most high-volume printed circuit assembly being sent outside the

United States, we have a unique challenge for testing the lower

volume/high turnover assemblies domestically. However, with a little

planning and the right contract manufacturer (CM), test does not need to

be an issue.

Source :Edadoc 2016/4/7>>Detail

With most high-volume printed circuit assembly being sent outside the

United States, we have a unique challenge for testing the lower

volume/high turnover assemblies domestically. However, with a little

planning and the right contract manufacturer (CM), test does not need to

be an issue.

Source :Edadoc 2016/4/7>>Detail

A variety of different test methods may be used for any one electrical

concern. This article will discuss the issues related to determining the

dielectric constant (Dk) and dissipation factor (Df or Tan-Delta).

Source :Edadoc 2016/3/30>>Detail

A variety of different test methods may be used for any one electrical

concern. This article will discuss the issues related to determining the

dielectric constant (Dk) and dissipation factor (Df or Tan-Delta).

Source :Edadoc 2016/3/30>>Detail

Printed circuit board

assembly (PCBA), starting with the plated through-hole, later evolving

to surface mount assembly, have been planar in two dimensions.

Components are mounted onto the PCBA in the x and y direction, where the

height, z direction, is controlled by the component height.

Printed circuit board

assembly (PCBA), starting with the plated through-hole, later evolving

to surface mount assembly, have been planar in two dimensions.

Components are mounted onto the PCBA in the x and y direction, where the

height, z direction, is controlled by the component height. How does the EDADOC PCBA factory work with 12 SMT lines? Edadoc PCBA factory devoted to cooperate with our clients, thus offers great product experience to end customers.

How does the EDADOC PCBA factory work with 12 SMT lines? Edadoc PCBA factory devoted to cooperate with our clients, thus offers great product experience to end customers.